Metal Associates

Distributors of Ferrous and Non-Ferrous Metals

Specializing in Copper, Brass, & Bronze

What are the benefits of using CDA 101, 102 OFHC copper wire?

Answer: CDA 101 (C10100) and CDA 102 (C10200) Oxygen-Free High-Conductivity (OFHC) copper wire offer significant advantages due to their high purity and minimal oxygen content, making them ideal for demanding applications.

Where to buy? - Metal Associates is a supplier of CDA 101, Alloy 101, OFHC and C10100 Copper Wire. Our copper wire fabrication support electronics, aerospace, and audio systems, and have these properties:

- Superior Electrical Conductivity: CDA 101 and 102 OFHC copper wires have exceptional electrical conductivity, with CDA 101 achieving a minimum of 101% IACS (International Annealed Copper Standard) and CDA 102 at 100% IACS. This high conductivity ensures minimal signal loss, making them perfect for high-frequency cables, superconducting wires, and precision electronics like circuit boards and connectors.

- Enhanced Corrosion Resistance: With oxygen content reduced to 0.0005% (CDA 101) and 0.001% (CDA 102), these wires resist corrosion better than standard copper, especially in industrial or humid environments. This durability is critical for applications like power cables and busbars in harsh conditions, extending service life.

- High Thermal Conductivity: OFHC copper’s thermal conductivity (386–394 W/m°C) efficiently dissipates heat, making it ideal for applications like induction coils, heat exchangers, and space heaters in aerospace and automotive industries, where thermal management is crucial.

- Resistance to Hydrogen Embrittlement: Unlike standard copper, CDA 101 and 102 resist hydrogen embrittlement in high-temperature or wet electrochemical environments, ensuring reliability in cryogenic applications, vacuum seals, and welding processes, such as in aerospace components or nuclear waste storage.

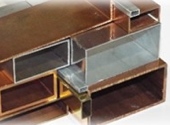

- Excellent Ductility and Workability: The high purity (99.99% for CDA 101, 99.95% for CDA 102) enhances ductility, allowing these wires to be easily formed into complex shapes without cracking. This is valuable for manufacturing intricate components like waveguides or custom audio cables.

- Improved Signal Transmission for Audio Applications: In high-end audio systems, CDA 101 is often preferred for speaker wires and connectors due to its ability to minimize signal distortion and deliver clearer sound. While the conductivity difference between CDA 101 and 102 is minimal (1%), CDA 101’s ultra-purity is marketed for superior audio performance.

These benefits make CDA 101 and 102 OFHC copper wires essential for applications requiring high performance, reliability, and precision, though their higher cost compared to ETP copper (C11000) should be weighed against specific project needs. We are ready to become your preferred supplier for these copper wires.

How much do you need and when do you want it delivered? Contact us today at: (800) 838-1978 or online from our Contact Us form.

Our Other Products

Contact Us

230 West Parkway

Unit 3-2

Pompton Plains, NJ 07444

Toll Free:

Phone:

Fax: (973) 835-7981

email: metals@rcn.com